Production

At Özkan Hidrolik, we meticulously manufacture power units that have been carefully designed and planned. Our process consists of the following stages:

Laser Cutting and Bending:

The metal sheets for power units are shaped with high precision using laser cutting machines, followed by bending processes to achieve the desired form.Welding and Cleaning:

Once the bending process is complete, our professional team welds the components. Necessary cleaning procedures are then applied to prepare the parts for painting.Painting Process:

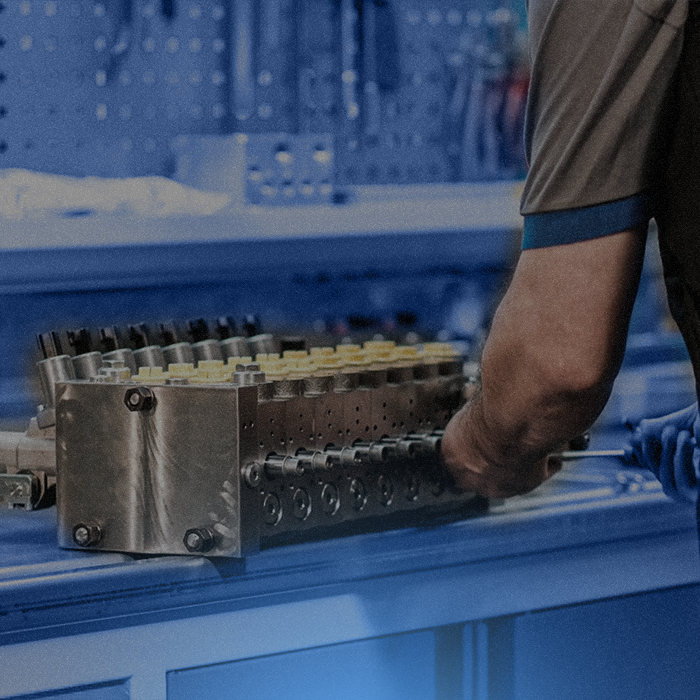

The parts are painted to ensure resistance against corrosion and to achieve an aesthetically pleasing appearance.Assembly:

Following the painting process, the components are assembled on the unit assembly line according to the circuit diagram and solid model specifications.Testing and Delivery:

Once assembly is complete, our quality control team conducts rigorous tests on the system. After successfully passing all tests, the products are prepared for delivery.

At Özkan Hidrolik, we prioritize quality and customer satisfaction at every stage to manufacture reliable and high-performance power units.